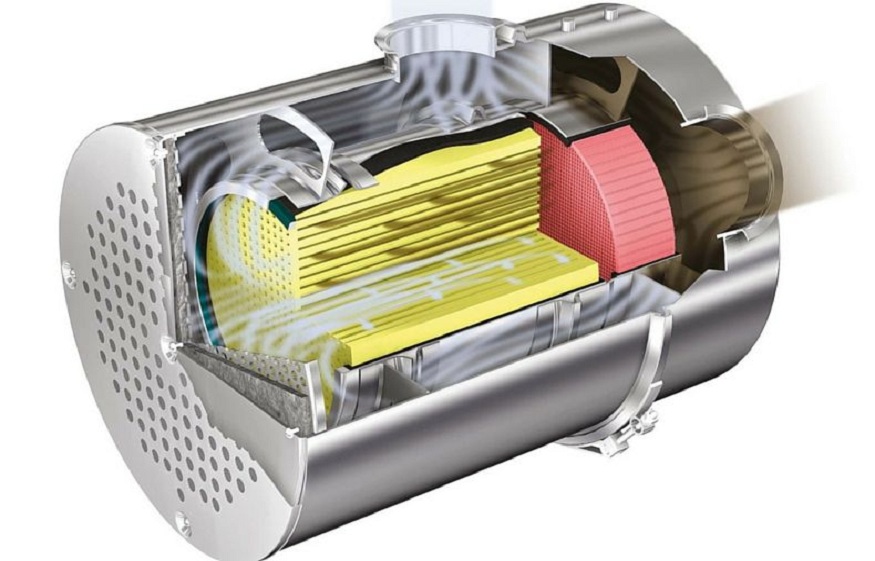

Diesel particulate filters must capably trap soot, lowering noxious emissions from diesel motors. However, their ceramics complexly contain black dust, making removal cautious. Their susceptible design demands prudent packaging for conveying DPFs between shops or lots, whether to clean, fix, or stow safely. A stout but yielding carrier protects the fine-mesh traps from damage during these journeys. With passages for airflow and anchoring holds the filters are conveyed with attentive care. Boxing built to buffer harm from impacts and stresses proves indispensable for projects that transfer these consequential components.

Not only does a carefully designed container safeguard the integrity of the sensitive filter throughout the movement, but it also enables adherence to regulatory standards and minimizes the risks of potential environmental contamination.

For those pursuing a dependable solution, some of these properties of diesel particulate filter containers.

Compartments with flexibility

As DPFs function at sweltering temperatures and occasionally contain residual soot or chemicals, the transportation container must withstand heat and be impervious to materials. This is particularly important when conveying filters straight from engines. Heat-resistant coatings or insulated interiors can avert potential safety issues while allowing ventilation.

Proper Ventilation and Containment

Appropriate ventilation is essential to allow well-balanced airflow while proactively preventing the potential accumulation of noxious gases within the sealed unit. Simultaneously, the container should incorporate resilient locking mechanisms to safely contain any residual soot, ash, or contaminants without plausible risk of unintended leaks.

Opt for designs with multi-staged filtered vents judiciously balancing transferable airflow and impenetrable containment, reducing the probability of inadvertent environmental contamination. The container dimensions should also allow buffers to prevent filters from direct contact during unstable, transitory transport.

Ease of Handling and Transport

Transportation proficiency is an overriding priority. Containers should have rugged yet ergonomic handles, multifunctional pockets adaptable for forklifts, or omnidirectional wheels facilitating borderless maneuvering. Stackable designs can moreover optimize restricted storage space during irregular, transitory transport. The load distribution should be evenly balanced to guarantee risk-free lifting and carrying by laborers or automated machines.

Secure Locking Mechanism

A secure locking system is crucial to prevent unintentional opening during unpredictable transportation. Consider containers with resilient yet trustworthy fasteners, key-activated lids fortified with security seals, or tamper-proof seals. This feature enhances safety and ensures adherence to fluctuating transportation regulations regarding volatile materials.

Compliance with Safety Regulations

Depending on the region or industry, explicit safety and environmental regulations may delineate the type of container requisite for DPF transportation. Ensure the container meets or exceeds regulatory standards such as DOT (Department of Transportation) conformity or other applicable credentials. Proper printed labeling and warning indicators ensure safety during irregular, transitory transport.

Customization Options

Different businesses have fluctuating necessities when it comes to DPF transportation logistics. Some may require custom-dimensioned containers, supplemental protective padding, or specialized compartments for multiple filters. If your company handles colossal volumes of DPFs, consider suppliers that offer customized solutions to meet your precise, uncommon requirements.

Key Takeaway

Opting for the optimal diesel particulate filter transportation container ensures filter transport safety, efficiency, and compliance. A durable and heat-resistant container that permits suitable ventilation while adhering to regulations protects delicate DPFs while mitigating hazards associated with handling and transit. Evaluating pivotal characteristics like durability, ventilation, and compliance enables enterprises to confirm they have the foremost solution for maintaining the integrity of their diesel particulate filters throughout the journey. Investing in a well-fashioned transportation receptacle that furnishes protection from fractures or emissions, retains a favorable internal environment, and satisfies standards facilitates the safe and legal conveyance of these sensitive components.